The Northern Borders University is dedicated to elevating its executive work and development programs in alignment with the Kingdom's Vision 2030 goals. Specifically, the College of Engineering's work teams are focused on completing tasks with precision and efficiency, including various projects and programs. Following the university's decision to prioritize mining as a significant direction, the College of Engineering has played a crucial role in advancing this focus, aligning with its vision for excellence in engineering education, research, and community service. Extensive scientific studies across different areas of Saudi Arabia have highlighted the prevalence of sand deposits, covering approximately 33% of the kingdom's total area, which amounts to about 635,000 km2 as the sands of the Empty Quarter, the Great Nafud, Dahna, and Jafurah (which are the largest sand seas in the Kingdom) occupy about 90% of the total sand deposits located in the Kingdom. Assessing sand deposits as potential sources of certain economic minerals and evaluating their compatibility with concentration and physical separation processes can significantly influence the development of the surrounding social landscapes. Consequently, His Excellency, the President of the Northern Border University, issued a decision on 06/25/1443 to establish a Mining Research Unit at the College of Engineering. The team in charge of this initiative has been tasked with acquiring cutting-edge scientific equipment in the mining field in line with the center's vision and objectives. The Mining Research Unit at the College of Engineering encompasses the following laboratories:

X-ray Diffraction Laboratory:

This laboratory contains a device for identifying minerals using X-ray diffraction technology (Figure 1), which is a device commonly used to identify unknown crystalline materials such as minerals and inorganic compounds while identifying these materials is of great importance for studies in the fields of geology, environmental sciences, materials science, engineering, and biology. Other application areas are the characterization of crystalline materials, identification of fine-grained minerals such as clays and thin mixed layers that are difficult to detect visually and may contain important economic minerals, determination of the three-dimensionality of the unit cell, and measurement of sample purity.

|

Figure (1): X-ray diffraction device |

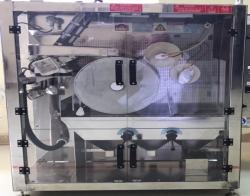

Electrostatic separation laboratory

This laboratory contains a device for electrostatically separating metals (Figure 2) based on their electrically charged sides with either negative or positive charges in several ways. It is frequently used in the metal processing industry and is one of the basic steps for separating valuable metals from non-valuable parts (impurities). This step allows the production of high-quality metals needed to create different valuable products.

|

Figure (2): Electrostatic metal separation device |

Grinding and crushing laboratory

It is one of the largest laboratories in the Mining Research Unit, as it contains many devices such as the magnetic separation device (Figure 3), which is a multi-use technology but is mostly used in the field of mineral processing, based on the differences in their magnetic properties to achieve the separation process. Since minerals consist of different components, some may be more or less magnetic than others, which allows for separation when exposed to a magnetic field. The laboratory also contains a high-intensity dry magnetic separation device (Figure 4), which is a device used to purify dry minerals and waste materials and works to separate ferromagnetic minerals and weakly magnetic minerals from non-magnetic ones.

|

Figure (3): Magnetic separation device for metals |

|

Figure (4): High intensity dry magnetic separator |

The Mining Research Unit of the Faculty of Engineering also contains many other auxiliary devices such as furnaces (Figure 5).

|

Figure (5): Electric oven device 1200 degrees Celsius |

Water separation tables for minerals (Figure 6), microscopes (Figure 7), mechanical vibrator (Figure 8), mechanical stirring and heating plates (Figure 9). It is expected that the Mining Research Unit at the Faculty of Engineering will be equipped with the latest equipment for grinding and crushing samples to prepare them for the separation process according to the required size.

| | |

Figure (6): Water separation table for minerals | Figure (7): Binocular microscope | Figure (8): Mechanical vibrating device |

|

Figure (9): Mechanical stirring devices and heating plates |

The Mining Research Unit at the College of Engineering has cooperated with many universities and research centers inside and outside the Kingdom, such as Najran University and the Egyptian Nuclear Materials Authority, in order to maximize the benefit of publishing scientific research in many fields. Its research production has so far reached about six researches, which are the first of its production in less than a year.